Our 450mm Width Cold Roller delivers ±0.005 mm precision for Stainless Steel Cold Rolling—achieving 4× tighter tolerances than used cold rolling mill systems while enabling dynamic width adjustment (100–450 mm) and 30 m/min speeds for aerospace, medical, and electronics applications.

EmailMore

This 1200mm Wide Cold Rolling Mill features a revolutionary 20-High Reversible Cold Rolling Mill design that achieves ±0.005mm tolerances on 20-ton coils – delivering 400% higher precision than conventional used cold rolling mill equipment while enabling bidirectional processing at 600 m/min for critical thin-strip applications.

EmailMore

This 4-High Cold Rolling Machine delivers industry-leading ±0.001mm tolerances and 25% energy savings, enabling high-precision processing from pharmaceutical foil to automotive alloys – outperforming conventional used cold rolling mills while providing retrofit-ready precision upgrades for existing production lines.

EmailMore

This integrated twin-stand solution delivers industry-leading thickness precision (±0.001mm) and energy efficiency (28% consumption reduction), enabling high-volume production of premium strips from battery foil to stainless steel – outperforming conventional single-stand mills while providing retrofit solutions for used rolling mill assets.

EmailMore

Main leveling machine: 6-row 19-roll structure, roll diameter 65mm, power 55kW Lenze servo length fixing system: 11kW Pneumatic clutch shearing machine: 11kW Gantry stacking system: 4-meter capacity

EmailMore

1. Core Mechanical Specifications Roll configuration: 19-roll staggered cluster design (referencing advanced leveling mechanics 2) Main drive power: 55 kW motor ensuring consistent torque Material compatibility: Processes 0.5-12mm thickness × 1000-1350mm width coils Throughput: 60,000+ tons annually (calibrated for this refurbished leveling machine) 2. Precision Control Systems Length control: Yaskawa servo system (15 kW) with ±0.5mm tolerance Automation interface: Brand-new Siemens PLC with HMI touchscreen Adaptive calibration: Dynamic pressure adjustment for varying material yields 3. Refurbishment Enhancements Structural integrity: Frame reinforcement and roll re-grinding (±0.002mm tolerance) Drive modernization: Replaced gearbox and bearing assemblies Safety compliance: Upgraded emergency stops (3.0 m/s² deceleration 2)

EmailMore

For sale: 90% new 0.3-3.0×1650 high-speed servo leveling and cutting line. 4-row 15-roll leveling unit, roll diameter 80mm, power 75kW Japanese Yaskawa servo length positioning system, power 11kW Pneumatic clutch shearing machine, power 15kW Gantry stacking system, 4.5-meter capacity in leveling machine: 6-row 19-roll structure, roll diameter 65mm, power 55kW

EmailMore

Acquire a near-new Foshan 750mm 4-High Tandem Cold Rolling Line featuring precision Work Roll Driven torque delivery, micron-level Electric Screwdown control, powerful 770KW/355KW motors, and seamless Turnkey Service integration for immediate high-quality strip production.

EmailMore

Basic Parameters: Processing Width: 1650mm (max material width) Material Thickness Range: 0.3-3.0mm (standard) | Special design available for 0.2-4.0mm Line Speed: 30-180 m/min (servo-controlled) Leveling Accuracy: ≤1mm/m (flatness standard) Annual Capacity: 150,000-250,000 metric tons (depending on material grade) Major Sections & Technical Highlights Entry Section Hydraulic expanding mandrel uncoiler (Ø500/600/700mm optional) Servo-controlled back tension system (22KW AC servo motor) Automatic coil car with V-type support Leveling Section 19-roller precision leveler (4-high configuration) Work roll diameter: Ø60mm (hard chrome plated) Support roll diameter: Ø180mm Servo-driven leveling adjustment (0.01mm precision) Cutting System Hydraulic flying shear (maximum cutting thickness 3.0mm) Siemens servo control system (1ms response time) Rotary encoder positioning (±0.2mm accuracy) Stacking & Output Automatic counting stacker (electromagnetic separator) Cross conveyor with rubber-coated rollers Output table with adjustable stopper Automation & Control Features Mitsubishi FX5U PLC control system 15" HMI touchscreen with multi-language interface Automatic length setting (0-9999mm programmable) Production data recording (count/length/speed) Remote monitoring capability (optional) Performance Advantages High-speed servo synchronization (±0.1mm length tolerance) Energy-saving design (regenerative braking system) Quick changeover (tool-free roll adjustment) Vibration-damping frame structure Material Compatibility Carbon steel (SPCC/DC01 etc.) Stainless steel (304/430 etc.) Aluminum alloy (1000/3000 series) Galvanized/Painted coils Quality Assurance Laser-calibrated leveling accuracy 72-hour continuous run test before delivery ISO 9001 certified manufacturing process *(Note: This 1650mm servo-leveling line represents advanced Chinese equipment manufacturing capability, combining German servo technology with Japanese control systems for high-precision metal processing.)* Optional Configurations: Automatic lubrication system Air knife cleaning device Protective film application unit Automatic width adjustment system

EmailMore

This 1450mm single stand mill delivers ±0.01mm precision at 900m/min with 6 hi reversing cold rolling technology, processing 28-ton coils for automotive-grade steel at 50% cost savings

EmailMore

With a maximum width of 670 mm and a minimum thickness of 0.015 mm. It can roll stainless steel, copper, ferronickel alloy, nickel, silicon steel, molybdenum and titanium. Sendzimir 20-high rolling mill (introduced from Belgium), equipped with French DMS and ABB electrical control system. Designed material width: 600 mm - 1050 mm, material thickness: 0.02 mm - 0.2 mm, speed: 300 - 600 m/min.

EmailMore

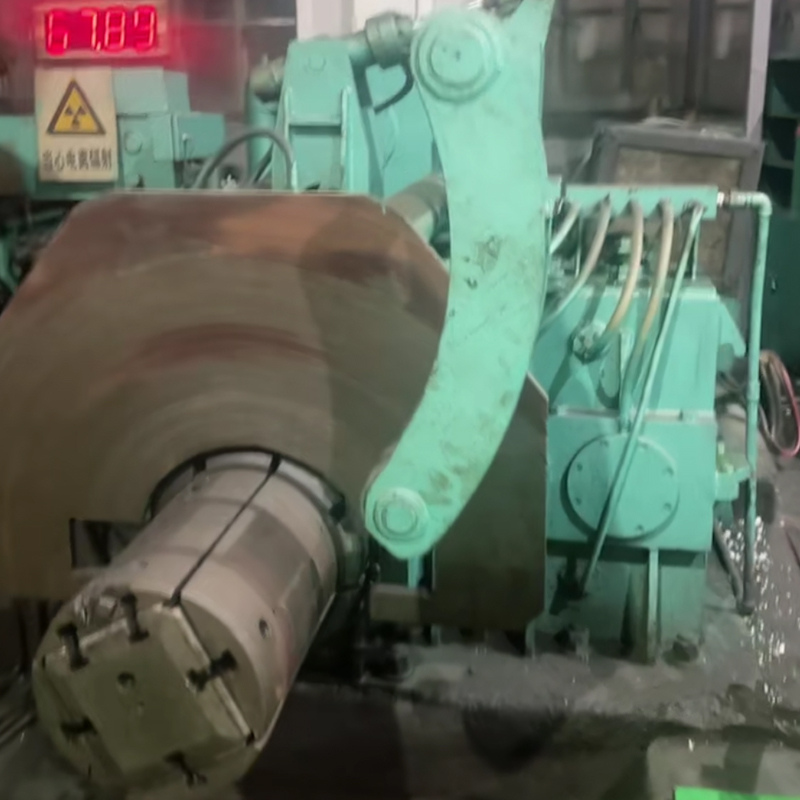

Taiwan-made 1350 slitting line in operation. Tool shaft diameter: 200mm Power for tool shaft: 55KW Power for seamless winding: 75KWSeamless winding: 132kW

EmailMore