This 850mm slitting line features a 130mm main arbor driven by a 45kW motor and a powerful 75kW recoiler, delivering enhanced slitting and rewinding performance for reliable coil processing operations.

EmailMore

This 850mm slitting line features a 120mm main arbor driven by a 37kW motor and a 45kW recoiler, offering a compact and efficient solution for precision coil slitting operations.

EmailMore

This 1650mm refurbished slitting line features a 220mm main arbor, 90kW main motor, 225kW support arm type recoiler, dual-cone uncoiler, and comes with 60 blades, ready for precision coil slitting operations.

EmailMore

This 1650mm slitting line, manufactured by Texiang Machinery and started up in September 2020, is a modern, high-precision coil processing line capable of handling 30-ton coils with material thickness up to 6.0mm for mild steel and 4.0mm for stainless steel. Featuring high-speed operation at 1000 rpm, it achieves excellent slitting quality with width tolerance of ±0.30mm, straightness of 0.35mm/m, and burr height ≤0.35mm. The line can slit strips as narrow as 50mm and includes an efficient scrap handling system, all within a compact 30m × 8m footprint.

EmailMore

This 650mm hot rolling mill, manufactured by Tianjin Tianzhong in 2012, features two 3-high roughing mills, two edgers, and 10 finishing stands (6 two-high and 4 four-high) with total installed power exceeding 20,000kW, capable of processing slabs up to 10 meters in length into 4.5-ton coils of mild steel and low carbon alloy steel.

EmailMore

This 550mm hot rolling mill, manufactured by Hebei Tianze in 2010, features a roughing mill (3Hi), two edgers, and 8 finishing stands (2Hi & 4Hi), capable of rolling mild steel and low carbon alloy steel from 150mm slabs to 1.3-5.7mm finished coils.

EmailMore

This 1200mm 20-high cold rolling mill, manufactured in 2006 and shut down in 2018, features AGC screw-down system, collapsible reels, and is capable of rolling stainless steel down to 0.1mm thickness at speeds up to 780 m/min.

EmailMore

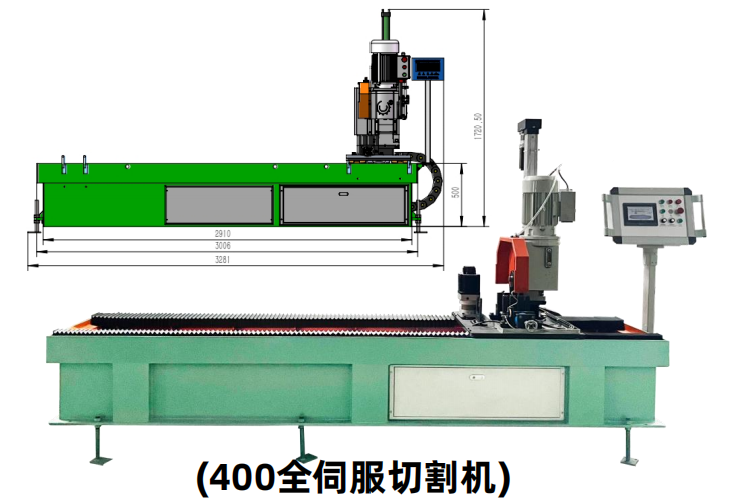

400 Full-Servo Cutting Machine:Utilizing full-servo drive technology, it achieves high-precision cutting of stainless steel welded pipes with length tolerance within ±0.3mm, meeting the precise processing requirements for pipes up to ≤89mm in diameter.

EmailMore

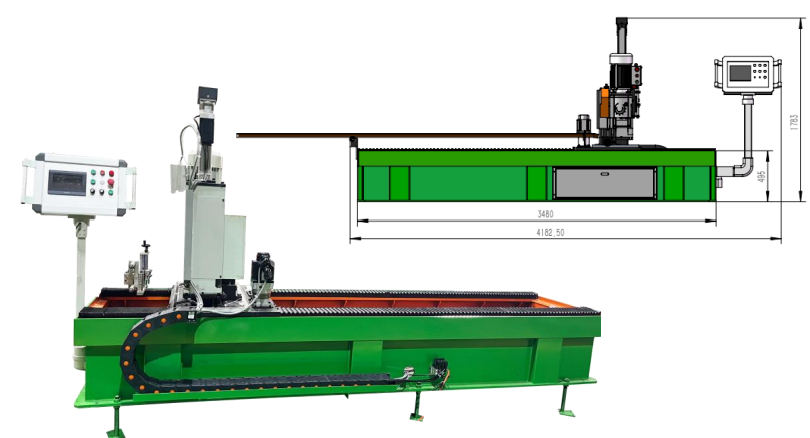

355 Full-Servo Cutting Machine:Utilizing a full-servo motor control system, it achieves high-precision stainless steel welded pipe cutting with length tolerance within ±0.3mm, while offering the dual advantages of energy efficiency, environmental friendliness, and stable operation.

EmailMore

Titanium Pipe Welding & Coiling Production Line :Fully automatic high-precision stainless steel and titanium thin-walled welded pipe production line, integrating welding, forming, and coiling for efficient and stable production of Φ6-25mm precision pipes.

EmailMore

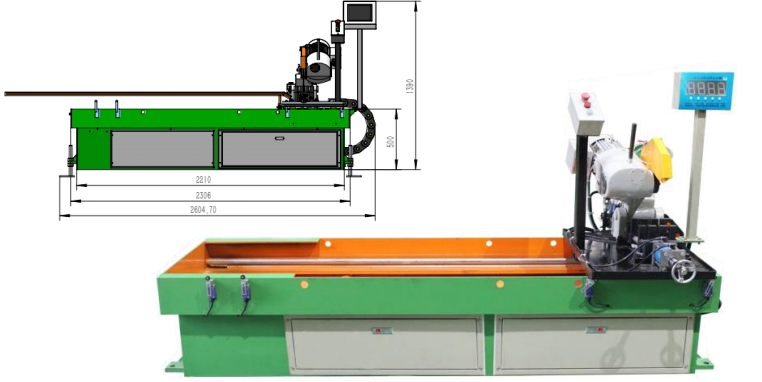

315 Cutting Machine:Stable, efficient, and precise cutting, ideal for processing various thin-walled pipes.

EmailMore

This integrated 680mm rolling line efficiently transforms billets into finished coils via a heavy-duty roughing mill and a continuous 9-stand finishing train.

EmailMore